How Is Seamless Steel Pipe Manufactured?

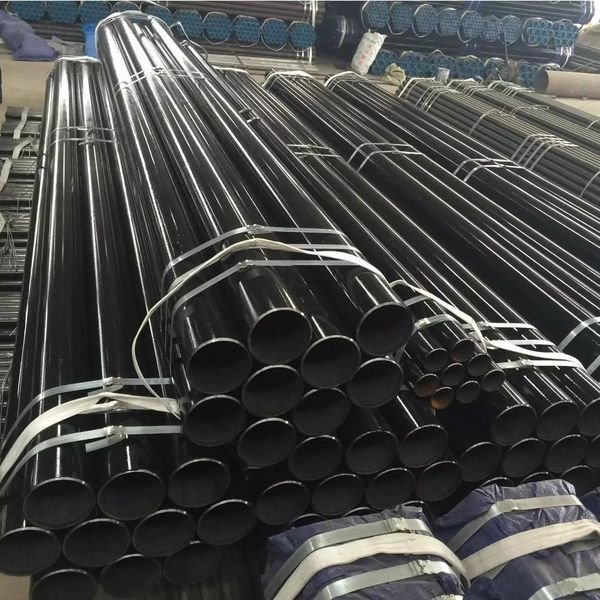

Seamless steel pipes find very important applications in the oil and gas, petrochemical, construction, automotive, and power industries. Seamless pipes have no joints or seams in them, making them compatible with high-temperature, high-pressure, or highly corrosive conditions in comparison to welded pipes.

But what actually is the process of making seamless steel pipes? Manufacturing is advanced, with high temperatures, accuracy engineering, and good quality control. Here is the main production process, materials applied, and technologies employed in the manufacture of seamless steel pipes.

What Is a Seamless Steel Pipe

A seamless steel pipe is a hollow cylindrical product that is made from a solid steel billet completely without the presence of welds. It is used where strength, uniformity, and pressure resistance are needed. Some common applications are:

- Oil and gas pipelines

- Boiler tubes

- Hydraulic cylinders

- Automotive components

- Structural and mechanical uses

Step-by-Step Seamless Steel Pipe Manufacturing Process

The process generally involves the following steps:

1. Raw Material Selection (Billet or Round Bar)

The operation starts out with a solid round steel bar or billet, typically made of carbon steel, alloy steel, or stainless steel. Most critical is the condition of the billet—it must be clean, homogeneous, and free from internal defects.

Billets typically are preheated to about 1200°C (2200°F) in order to make them ductile to shape.

2. Piercing (Making the Hollow Core)

Heated billet is then rolled over into a piercing mill, which pushes it through a set of rotating rolls. At the same time, a piercing plug or mandrel is pushed into the middle. This produces a basic hollow shell from the solid billet and is referred to as rotary piercing.

This is one of the most crucial steps, as it forms the seamless tube without welding.

3. Elongation and Rolling

After piercing, the hollow shell (a “hollow bloom”) is stretched and reduced in diameter by rolling mills. There are several ways to this operation, including:

- Plug Mill Process

- Mannesmann Process

- Assel Mill Process

- Mandrel Mill Process

All of them involve thinning the wall and shaping the outer diameter by passing the shell through a sequence of rolling stands, with or without a mandrel inside.

4. Sizing and Stretch Reduction

In order to achieve the precise outer diameter and wall thickness, the pipe is sent through sizing mills or stretch reducing mills (SRM). The treatment serves to ensure the pipe meets dimensional and tolerance requirements, especially in applications requiring strict tolerances like pressure vessels or oil & gas.

5. Heat Treatment

Based on the desired properties and grade of steel, the pipe is subjected to heat treatment processes such as:

- Normalizing

- Annealing

- Quenching and Tempering

This improves the mechanical properties such as hardness, toughness, and corrosion resistance.

6. Straightening

The pipe may get slightly curved after heat treatment. It is passed through a straightening machine in order to make it have an even and accurate shape, especially for long pipes of length.

7. Cutting

Pipes are cut to certain lengths with saws, cutting torches, or cold-cutting machines. Common lengths are 6 meters and 12 meters, although they can be cut as required.

8. Finishing and Surface Treatment

Outer and inner pipe surface cleaning is done through:

- Shot blasting

- Pickling

- Phosphating

- Coating (varnish, oil, or paint)

This provides protection to the pipe while in storage and transportation and improves corrosion resistance.

9. Inspection and Testing

Quality control is critical. Seamless pipes are tested for:

- Dimensional accuracy

- Mechanical properties

- Chemical composition

- Hydrostatic pressure

- Ultrasonic or eddy current testing

- Surface defects

Only those pipes that pass all tests successfully are certified and packaged for shipment.

Types of Seamless Pipe Manufacturing Methods

There are two main categories based on the application and size:

- Hot-Finished Seamless Pipe: Fabricated at high temperatures and typically employed for general structural or bearing pressure applications.

- Cold-Drawn Seamless Pipe: Second-time processed at ambient temperature; enhanced dimensional tolerances and surface quality, commonly employed in automotive and instrument tubing.

Advantages of Seamless Steel Pipe

- No Welds or Critical Points: Uniform strength along the pipe body.

- High Pressure Resistance: Most suitable for oil, gas, steam, and fluid transportation.

- Corrosion Resistance: Especially if made of stainless or alloy steel.

- Enhanced Dimensional Accuracy: Especially in cold-drawn varieties.

- Flexible Applications: From industrial to precision machinery.

Conclusion

Smooth steel pipe production is an extremely specialized process that transforms solid steel billets into hard-wearing, high-performance tubing with no welding. From rotary piercing to finishing and inspection, all steps guarantee the final product is of high-industry standards.

Regardless of whether used in deep-sea oil wells, boiler plants, or race car components, seamless pipes are still a cornerstone of modern engineering and construction.

Frequently Asked Questions (FAQ)

1. What is the biggest difference between seamless and welded steel pipes?

Seamless pipes are made from a solid billet and have no welded seams, giving them evenly distributed strength and better pressure resistance.

Seamless pipes are made by rolling and welding a steel coil or plate, conceivably with an evident seam along their length. Welded pipes are less expensive but not always appropriate for high-pressure situations.

2. What steels are used to make seamless pipes?

Common materials employed are carbon steel, alloy steel, and stainless steel. The choice depends upon the application, be it corrosion resistance, temperature, or pressure.

3. Where do seamless steel pipes commonly occur?

Seamless steel pipes find widespread applications in the oil and gas industry, power plants, automobile industry, chemical processing, boiler plants, and structural engineering.

4. Do seamless pipes last longer than welded pipes?

Yes. Because seamless pipes are produced without a weld seam, they have homogeneous mechanical properties along the full length and can sustain higher pressure, temperature, and stress than welded pipes.

5. What is the normal length of seamless steel pipes?

Standard lengths are usually 6 meters or 12 meters, but project-specific lengths can also be produced. Pipes can also be supplied in fixed or random lengths as required by the order.

6. What tests are performed on seamless pipes before delivery?

Seamless pipes undergo rigorous non-destructive and mechanical tests, including:

- Internal/external defect examination through ultrasonic or eddy current testing

- Hydrostatic pressure testing

- Tensile and hardness testing

- Chemical composition testing