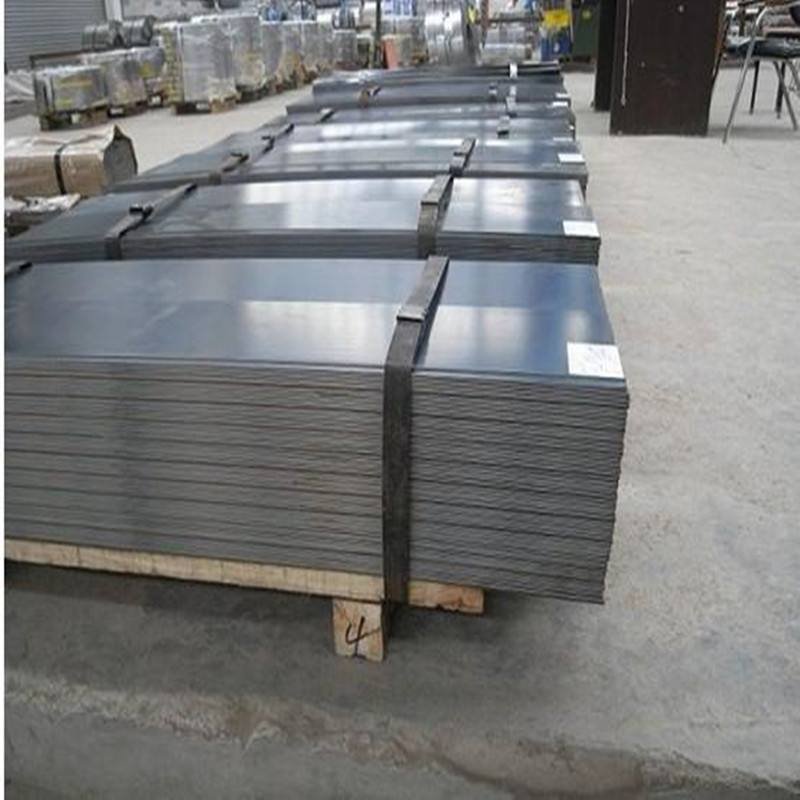

Description

## Core technology and features

1. **Raw material basis:** High-quality hot-rolled pickled coil (hot-rolled coil after removing iron oxide scale).

2. **Core technology:**

* **Cold rolling:** Strong plastic deformation at room temperature through a large pressure rolling mill (such as a reversible rolling mill, a continuous rolling mill). Significantly reduce thickness, improve strength and hardness, and improve dimensional accuracy and plate shape.

* **Annealing:** Key process! The cold hard coil is heated in a protective atmosphere (to prevent oxidation) (continuous annealing CAL or hood annealing BA) to eliminate work hardening, restore plasticity and toughness, and accurately control the internal structure to obtain target properties (such as deep drawability).

* **Smoothing (quenching and tempering rolling):** Slight rolling (usually 0.5%-3% reduction rate) to eliminate the yield platform, improve the plate shape, control the surface roughness, and obtain more uniform mechanical properties and ideal surface conditions.

* **Finishing:** Including oiling (rust prevention), coiling, inspection, packaging, etc. The surface can be specially treated (such as passivation).

3. **Core features:**

* **Excellent surface quality:** High finish, silvery white metallic luster, no iron oxide. Surface roughness (Ra) can be precisely controlled (rough or smooth) to meet the requirements of subsequent processing such as spraying and electroplating. Common surface grades: commercial grade (CQ), stamping grade (DQ), deep drawing grade (DDQ), super deep drawing grade (EDDQ/SUFD), super super deep drawing grade (SEDDQ/SUSD) and O5 grade high surface required by home appliances/automobiles.

* **Extremely high dimensional accuracy:** Strict thickness tolerance control (up to ±0.02mm), small width tolerance, and excellent plate shape (flatness).

* **Excellent and controllable mechanical properties:** Through the precise combination of rolling, annealing and leveling processes, the strength (tensile strength, yield strength), hardness, elongation (plasticity) and forming properties (n value, r value) of the product can be flexibly adjusted to meet various needs from ordinary structures to ultra-deep stamping.

* **Thinner thickness range:** Typical thickness range is between **0.15mm and 3.0mm**, especially good at producing ultra-thin specifications (<1.0mm) that are difficult to achieve with hot rolling.

* **Uniform and dense structure:** Cold rolling + annealing process forms a fine and uniform ferrite grain structure.

## Main materials

* **Mild steel (Mild Steel):** Most common, such as SPCC (JIS), DC01 (EN), SPHC (SPCD/SPCE after cold rolling, etc.), Q195/Q235B (grade after cold rolling).

* **Carbon structural steel:** Specific strength requirements.

* **High-strength low-alloy steel (HSLA):** Improve strength while ensuring good formability, reduce weight and save energy.

* **Bake-hardened steel (BH Steel):** The strength is further improved during the coating and baking process, and is used for automotive outer panels.

* **Dual-phase steel (DP Steel):** Both high strength and good formability.

* **Some special purpose steels. **

## Core performance advantages

1. **Excellent surface and dimensional accuracy:** Lays the foundation for high-quality painting, electroplating, fine stamping, and appearance parts manufacturing.

2. **Excellent forming performance:** Especially deep drawing and ultra-deep drawing products, with high elongation, high n value (work hardening index) and high r value (plastic strain ratio), suitable for deep drawing and stretching of complex shapes.

3. **Balance of high strength and good plasticity:** A wide range of performance spectrum from soft deep drawing materials to high-strength structural materials can be provided through process and material selection.

4. **Good welding performance:** Low carbon steel material has excellent weldability.

5. **Consistent mechanical properties and plate shape:** The performance of the whole roll and between rolls is stable, ensuring production continuity and product consistency.

6. **Wide adaptability to subsequent processing:** Easy to shear, stamp, bend, weld, spray, electroplating (galvanizing, tinning), lamination and other processing.

Reviews

There are no reviews yet.