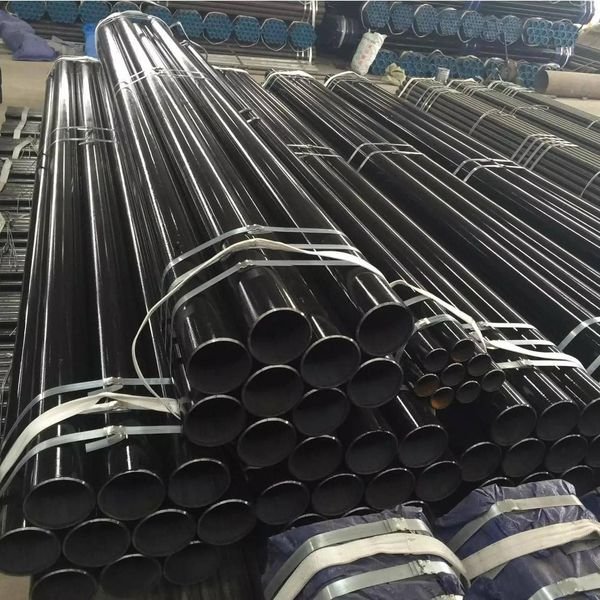

Description

## Core Manufacturing Process and Features

1. **Raw Materials:** High-quality solid round steel billet (tube billet).

2. **Core Process:**

* **Piercing:** The heated tube billet is punched into a hollow tube (capillary) on a piercing machine.

* **Hot rolling (main method):** The tube is rolled and stretched through multiple passes on a hot rolling tube unit (such as an automatic tube rolling mill, a continuous tube rolling mill, a precision tube rolling mill, a three-roll tube rolling mill, a tube jacking mill, etc.) to reach the required size and wall thickness. Then it goes through processes such as sizing (reducing), cooling, straightening, and cutting heads and tails. It has high production efficiency and is suitable for medium-thick wall and large diameter tubes.

* **Cold rolling/cold drawing:** Hot-rolled tubes or semi-finished tubes are further processed at room temperature (using a cold tube rolling mill or a cold drawing machine). It can produce **high-precision, high-finish, thin-walled, small-diameter** steel tubes, significantly improving dimensional accuracy, surface quality, and mechanical properties (strength, hardness).

* **Heat treatment:** According to the needs, normalizing, annealing, quenching + tempering and other heat treatments are carried out to optimize the organizational structure, eliminate stress, and obtain the required mechanical properties.

3. **Core features:**

* **No weld:** The biggest advantage is that it fundamentally avoids the defects that may exist in the weld (such as pores, slag inclusions, incomplete penetration, uneven performance of the heat-affected zone), and significantly improves the overall strength, pressure bearing capacity, fatigue resistance and safety of the pipe.

* **Good cross-sectional uniformity:** The wall thickness distribution is more uniform and the concentricity is high.

* **Excellent pressure bearing capacity:** Especially suitable for harsh working conditions with high pressure, high temperature, high stress or impact load.

* **High material purity:** A wider range of higher-grade steels (such as high-alloy steel) can be selected.

* **Wide range of sizes:** The outer diameter ranges from a few millimeters (capillary) to more than 600mm or even larger, and the wall thickness ranges from ultra-thin wall to extremely thick wall.

* **Controllable surface quality:** The hot-rolled tube has oxide scale on the surface (can be removed by pickling), and the cold-rolled/cold-drawn tube has a smooth surface with high precision.

## Main materials

Depending on the application requirements, a variety of materials can be selected:

* **Carbon steel:** Such as 10#, 20#, 35#, 45# (GB standard), ASTM A106 Gr. B, API 5L Gr. B, etc.

* **Alloy steel:** Such as 16Mn (Q345B), 15CrMo, 12Cr1MoV, 30CrMo, 42CrMo (for high strength, heat resistance, wear resistance, etc.).

* **Stainless steel:** Such as 304, 316, 316L, 321, 347, duplex steel 2205/2507 (ASTM A312, ASTM A269, etc.), used for corrosion resistance, high temperature resistance, food/pharmaceutical grade applications.

* **Special alloys:** Such as high-temperature alloys, nickel-based alloys, etc., used in extreme environments.

## Core performance advantages

1. **High strength and high pressure bearing capacity:** No weld weaknesses, high overall strength, especially suitable for high-pressure systems.

2. **Excellent temperature resistance:** Good high-temperature strength and low-temperature toughness, suitable for boilers, heat exchangers and low-temperature environments.

3. **Excellent corrosion resistance (especially stainless steel/alloy tubes):** Suitable for corrosive environments such as chemical, petrochemical, and marine.

4. **Good processing performance:** Can be bent, expanded, shrunken, cut, etc. (depending on the material and state).

5. **High reliability and safety:** No weld hidden dangers, long service life, and lower risks in critical applications.

6. **High dimensional accuracy (especially cold-rolled/cold-drawn tubes):** Meet occasions with strict dimensional requirements such as precision machinery and hydraulic systems.

## Main application areas (critical and demanding occasions)

Seamless steel pipes are widely used in areas with extremely high requirements for safety, reliability and performance due to their excellent pressure bearing, temperature resistance, corrosion resistance and seamlessness.

Reviews

There are no reviews yet.